Over the years I have struggled with the Conceptual Massing Environment (CME) in Revit. It is not easy to use, and is not at all well integrated with the rest of Revit. However, I have learnt a huge amount about how to get it to do what you want (or not!). I have tried to document some of the tips and tricks on this blog and during various conference presentations that I have given at RTC & BILT .

Here is a summary / index of all the relevant posts on this blog:

Conceptual Massing Environment

Rival Revit Environments - Traditional vs Conceptual Massing Environment (CME)

Creating Traditional Forms using Conceptual Massing

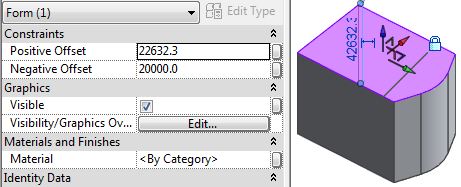

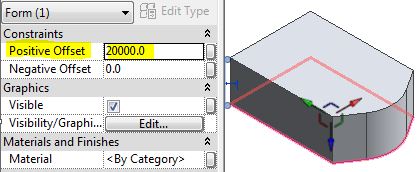

Part 1 - ExtrusionExtrusion Offset Properties

Part 2 - Blend

Part 3 - Revolve

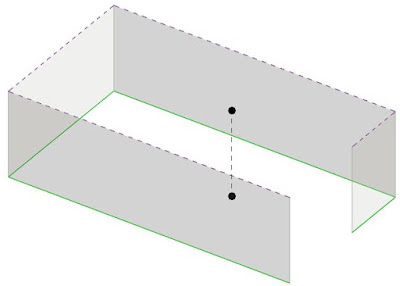

Part 4 - Sweep

Part 5 - Swept Blend

Part 6 - Loft

- Creating Tightly Curved Swept Blends

- Creating Sinuous Curve Swept Blends - Part 1

- Creating Sinuous Curve Swept Blends - Part 2

Adaptive Components

Adaptive ComponentsAdaptive components are a subset of the Conceptual Massing Environment:

- A Dozen Reasons Not to Use Adaptive Components

- Reasons to Use Adaptive Components

- Swept Blend using Profile in Adaptive Component

- Egress Path using Adaptive Components (Life Safety Plan)

- Egress Path (Update) and Shape Handle Points

- Mona Lisa's Eyes Follow The Revit Camera

- Adaptive Component Origins

- Zero Length Lines are Possible in Adaptive Components

Repeaters

Repeaters are a kind of array, in the CME world . . .Modelling Santiago Calatrava's Gare do Oriente (Lisbon) using Repeaters:

Step 2 Putting roof panels on top of the rig . . .

Step 3 Creating the structural elements and placing on the rig

Step 4 Adding Struts to the structure

Step 5 Assembling the Array of Structural ColumnsStep 3 Creating the structural elements and placing on the rig

Step 4 Adding Struts to the structure

Revit Ideas - Vote to Improve the Conceptual Massing Environment in Revit:

Some of the problems could be alleviated by the following capabilities - please vote for them on the Autodesk Revit Ideas wish-list if you agree:

- Control profile order during form creation

- Nominate Path during form creation