A few years back I posted a description of

how to create a complex custom hatch pattern for Revit - that example was for repeating octagons. Since then I have often needed to quickly create much simpler patterns such as stretcher bond elevation views for bricks, blocks and tiles. The Octagon pattern was quite complex and it still takes a while to get your head around the logic - so here is a much easier to follow set of examples:

Pattern Definition Format

The pattern file is a text file, saved with a '.pat' extension.

Definition of units (important for metric):

;%UNITS=MM

Each pattern definition has an * prefixed header : a title and description separated by a comma

*Stretcher 400x200, 400mm x 200mm stretcher bond

Drafting or Model definition:

;%TYPE=MODEL

Each line repeat (in the pattern) is described in one row of text, with comma delimited format. eg:

0, 1200, 1000, 0, 1000, 400, -1500

- Angle = angle of line from horizontal measured in an anti-clockwise direction

- Origin x = horizontal distance of start of line from setout point (always orthogonal)

- Origin y = vertical distance of start of line from setout point (always orthogonal)

- Shift u (x axis of line) = offset distance of start of repeat line measured parallel to start of line

(in the direction of the line, ie. to match the angle). The Shift values are measured from the start of the line, not from the setout point.

- Shift v (y axis of line) = offset distance of start of repeat line measured perpendicular to start of line

- Pen down = length of solid line measured in the direction of the line (optional - it draws a continuous line if omitted)

- Pen up = length of gap in the line before the next segment of the

line starts repeating (measured in the direction of the line); is

always a minus value. (optional - as per pen down)

NB. I have labelled the shift directions as u & v (not x & y, as Autodesk labels them) because the directions relate to the axis of the line, not the whole pattern - so a vertical line would have a u offset measured vertically (labelled as x direction by Autodesk, which is confusing).

Stretcher Bond Hatching Definitions

A typical staggered tile pattern (stretcher bond) consists of :

- a series of continuous horizontal lines at regular spacing;

- Short vertical lines that run between alternate horizontal lines, at a spacing equal to the length of the brick/block/tile

- Another set of short vertical lines that run between alternate horizontal lines, at a spacing equal to the length of the brick/block/tile - but these are typically offset horizontally by half a length and vertically by one pattern height.

These should almost always be defined as MODEL patterns, as they are meant to be dimensionally correct on the surface of the material.

There are actually two ways to define this:

Option 1 - separate definitions for the two vertical lines

*Stretcher-450x150-1/2, 450 x 150 1/2 stretcher bond

;%TYPE=MODEL

0, 0,0, 0,150

90, 0,0, 0,450, 150,-150

90, 225,150, 0,450, 150,-150

The first row defines the horizontal lines

0, 0,0, 0,150

- The lines are at zero degrees (horizontal)

- The first line starts at 0 offset from the origin, both x and y (0,0)

- The repeat has a shift of zero horizontally (x or u), and 150mm vertically (y or v) from the line origin (0,150),

- The next repeat is the same values (0,150) from the start of the previous repeat.

- The line is continuous, as the are no pen up/down values

The second row defines the first set of vertical lines

90, 0,0, 0,450, 150,-150

- The lines are at 90 degrees (vertical )

- The first line starts at 0 offset from the origin, both x and y (0,0)

- The repeat has a shift of zero vertically (u) , and 450mm horizontally (v) , from the line origin (0,450)

- The next repeat is the same values (0,450) from the start of the previous repeat.

- The line is segmented, 150mm solid, 150mm gap (pen up/down 150,-150)

The v shift in this instance is horizontal, perpendicular to the line, with a positive value to the left of the line origin (same as pattern setout point in this case).

- As the pattern is symmetrical, it makes no difference if the v shift value is positive or negative

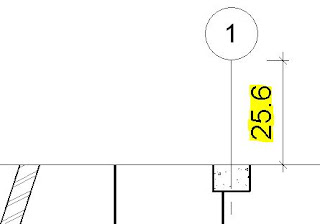

- Seen below in context, the pattern repeats in both directions from the origin:

The third row defines the second set of vertical lines

90, 225,150, 0,450, 150,-150

- The lines are at 90 degrees (vertical )

- The first line starts at 225mm x offset from the origin, and 150mm y offset from the origin (225,150) - ie. half a tile along and one tile up.

- The repeat has a shift of zero vertically (u) , and 450mm horizontally (v) , from the line origin (0,450)

- The next repeat is the same values (0,450) from the start of the previous repeat.

- The line is segmented, 150mm solid, 150mm gap (pen up/down 150,-150)

Option 2 - one definition for both vertical lines

*Stretcher-450x150-1/2, 450 x 150 1/2 stretcher bond

;%TYPE=MODEL

0, 0,0, 0,150

90, 0,0, 150,225, 150,-150

The first row defines the horizontal lines as per previous method

0, 0,0, 0,150

The second row defines the vertical lines

90, 0,0, 150,225, 150,-150

- The lines are at 90 degrees (vertical )

- The first line starts at 0 offset from the origin, both x and y (0,0)

- The repeat has a shift of 150mm vertically (u) , and 225mm horizontally (v) , from the line origin (150,225)

- The next repeat is the same values (150,225) from the start of the previous repeat.

- The line is segmented, 150mm solid, 150mm gap (pen up/down 150,-150)

- As the pattern is symmetrical, it makes no difference if the u and v shift values are positive or negative

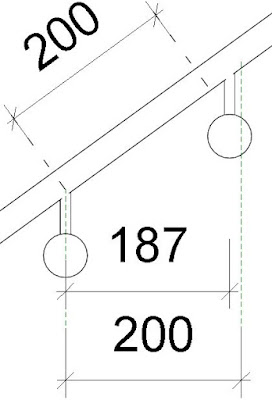

- Seen below in context, the pattern repeats in both directions from the origin:

One Third Shift Patterns

The same principles can be applied when the bond is staggered by differing proportions.

Option 1 - separate definitions for each vertical line

*Stretcher-450x150-1/3, 450 x 150 1/3 stretcher bond

;%TYPE=MODEL

0, 0,0, 0,150

90, 0,0, 0,450, 150,-300

90, 150,150, 0,450, 150,-300

90, 300,300, 0,450, 150,-300

90, 150,150, 0,450, 150,-300

- 90 degrees

- 150mm x line origin, 150mm y line origin

- Zero u shift repeat, 450mm v shift repeat

- 150mm Pen Down, 300mm gap (Pen Up)

90, 300,300, 0,450, 150,-300

- 90 degrees

- 300mm x line origin, 300mm y line origin

- Zero u shift repeat, 450mm v shift repeat

- 150mm Pen Down, 300mm gap (Pen Up)

Option 2 - one definitions for all vertical lines

*Stretcher-450x150-1/2, 450 x 150 1/2 stretcher bond

;%TYPE=MODEL

0, 0,0, 0,150

90, 0,0, 150,300, 150,-300

Horizontal shift (v) repeat has to be 2/3 of a tile (300mm)

As the joint offset is not half a tile, the same result can be achieved with a negative v shift repeat of -150mm:

0, 0,0, 0,150

90, 0,0, 150,-150, 150,-300

An offset by one third to the left could be achieved by a positive 150mm v shift:

0, 0,0, 0,150

90, 0,0, 150,150, 150,-300

Two Third Shift Patterns

Some patterns cannot have their vertical lines defined by only one row, as you can't define a consistent diagonal repeat. Therefore you must have multiple rows for the vertical lines.

*Staggered-450x150-2/3, 450 x 150 2/3 stretcher bond

;%TYPE=MODEL

0, 0,0, 0,150

90, 0,0, 0,450, 150,-150

90,

300,150, 0,450, 150,-150

The direction of stagger can be changed with the x origin value:

*Staggered-450x150+2/3, 450 x 150 2/3 stretcher bond

;%TYPE=MODEL

0, 0,0, 0,150

90, 0,0, 0,450, 150,-150

90,

150,150, 0,450, 150,-150

Flemish Bond

More complex brick patterns require extra rows of definition:

*Flemish-240x86, 240 x 86 (Australian Brick size) Flemish stretcher bond

;%TYPE=MODEL

0, 0,0, 0,86

90, 0,0, 0,360, 86,-86

90, 240,0, 0,360, 86,-86

90, 60,86, 0,360, 86,-86

90, 180,86, 0,360, 86,-86

You could continue this theme with increasing random looking patterns, but I'll leave that for you to figure out . . . . . .